Anaerobic digestion is the natural breakdown of organic materials into methane and carbon dioxide gas and fertiliser. This takes place naturally, or in an anaerobic digester. A typical anaerobic digester is a sealed vessel, or series of vessels, in which bacteria act without oxygen. The organic material contents need to be fully mixed and warmed, usually to blood temperature.

Biogas is formed during the anaerobic digestion of organic waste. It consists of methane (c70%) and carbon dioxide (c30%). After removing the carbon dioxide (and other trace gases using a variety of methods in a process known as upgrading) the remaining methane is known as Renewable Natural Gas or Biomethane.

Biomethane is virtually identical to natural gas, so that the uses for biomethane are therefore as varied as are those for natural gas. Generally, as regards AD plants, the biogas will be:

Burned in a conventional boiler and used as heat for surrounding buildings;

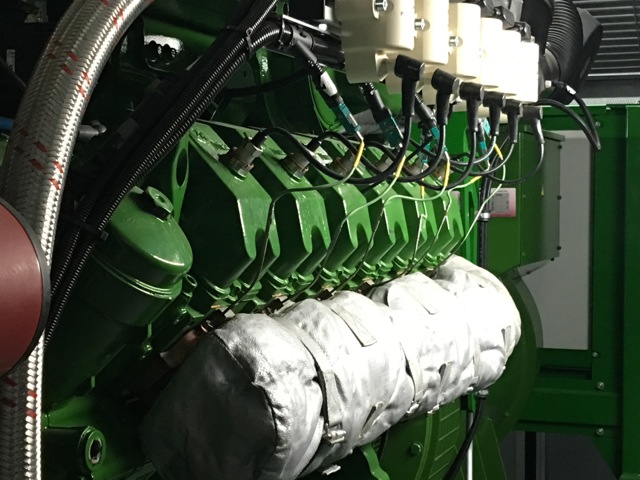

Burned in a gas engine to generate electricity

Feedstock (also known as substrate) is the material that is used in anaerobic digestion process. The feedstock doesn’t have to be waste; any biodegradable plant or animal matter that is not woody is a suitable feedstock for a digester. However, anaerobic micro-organisms cannot break down lignin, the complex polymer that gives plants their strength, which means that wood products, paper and straw will slow the digester. Some examples of feedstock streams are:

Slurry or manure;

Domestic or commercial food waste;

Food processing (industrial) waste;

Crops grown specifically for AD, as silage.

Biogas production is very much dependent on the type of feedstock used and will vary according to dry matter content, the energy left in the feedstock (if it has prolonged storage it may begin to break down), length of time spent in the digester, the type of AD plant and the purity of the feedstock.

The following is a table indicating potential biogas yields of different types of feedstock:

Feedstock Dry matter (percentage) Biogas yield m3/tonne

Cattle slurry 10 15-25

Pig slurry 8 15-25

Poultry 20 30-100

Grass silage 28 160-200

Maize silage 33 200-220

Maize grain 80 560

Rape meal 90 620

Wheat grain 85 610

Manure collected from cattle and pigs during periods of the year when they are housed, typically contain 6-10% dry matter. Dairy cattle typically produce between 42 kg and 64 kg (depending on body weight) of manure per day, if they are housed for 50% of the year that corresponds to c.7-11 tonnes pa per cow. The resource from the UK beef herd of 1.8 million will be less, as they typically spend less time housed, though may still be in excess of 5 million tonnes (wet) pa. There are also 4.9 million pigs in the UK and 20 million sheep. However, as sheep are kept almost entirely outdoors collecting their manure may not be practical.

Most AD plant will not rely on a single feedstock type and will generally use a combination of different feedstock types – see for example feedstock blends being used in current AD plant operating in Europe in Annex 3. Landowners / farmers in deciding whether to participate in this investment, should not concern themselves with full feedstock requirements of the plant. In addition to on-farm feedstock that may be available, it is the responsibility of the plant owner / operator to secure long-term feedstock supply contracts for the plant. On-farm activities are not expected to be able to supply all the plants’ feedstock requirements.

The quantity of feedstock needed is dependent on a number of factors, including feedstock type, dry matter content, AD process type used, feedstock residency time in digester, efficiency rating of turbines, size of digester, plant running time and so forth. To give a better indication of types and quantities of feedstock that may be required, Annex 3 shows key data for plants currently installed in the United Kingdom.

Digestate is the effluent coming from the digester at the completion of the digestion process. Digestate has nutrient value, so producers can apply digestate to land, much like manure. There are two types of digestate:

Fibre (a nutrient rich soil conditioner); and

Liquor (a liquid fertilizer)

Types of Anaerobic Digestion

Mesophilic/Thermophilic

Mesophilic systems operate at 25-45°C and thermophilic systems operate at 50-60°C or above. Thermophilic systems have a faster biogas production per unit of feedstock and m³ digester and there is greater pathogen kill. However, the capital costs of thermophilic systems are far higher, more energy is needed to heat them and they generally require more management.

Wet/Dry

The difference between what is considered a wet process and a dry process is quite small. Effectively, in wet AD the feedstock is pumped and stirred and in dry AD it can be stacked. Dry AD tends to be cheaper to run as there is less water to heat and there is more gas production per unit feedstock. However, wet AD has a lower set-up capital cost.

Continuous Flow/Batch Flow

Most digesters are continuous flow as opening the digester and restarting the system from cold every few weeks is a management challenge. They also generally give more biogas per unit feedstock and their operating costs are lower. Some dry systems are batch flow, however.

Single/Multiple Digesters

AD occurs in several stages. Some systems have multiple digesters to ensure each stage is as efficient as possible. Multiple digesters can give you more biogas per unit feedstock but at a higher capital cost, higher operating cost and greater management requirement. Most digesters in the UK are single or double digesters.

Vertical/Horizontal Plug Flow

Vertical tanks simply take feedstock in a pipe on one side whilst digestate overflows through a pipe on the other. In horizontal plug-flow systems a more solid feedstock is used as a ‘plug’ that flows through a horizontal digester at the rate it is fed in. Vertical tanks are simple and cheaper to operate, but the feedstock may not reside in the digester for the optimum period of time. Horizontal tanks are more expensive to build and operate, but the feedstock will neither leave the digester too early nor stay in it for an uneconomically long period.